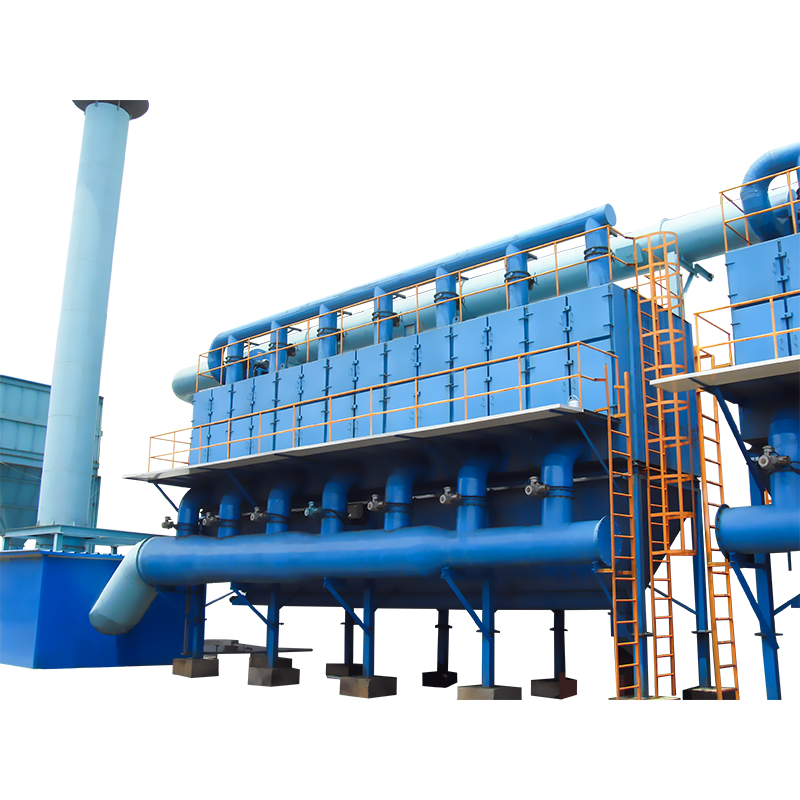

In the field of precision machining of modern industrial production, grinders are indispensable key equipment. While operating efficiently, they inevitably produce a large amount of metal dust. These fine dusts not only pollute the production environment and affect product quality, but also pose a potential threat to the health of operators. Therefore, efficient and reliable dust removal equipment is particularly important. Bag type dust collector for grinding machines, with their unique technical advantages, stand out among many dust removal equipment and become the first choice of many companies.

The core of the bag type dust collector for grinding machine lies in its efficient filtration system. High-quality filter bag materials such as polyester fiber, PPS (polyphenylene sulfide), PTFE (polytetrafluoroethylene), etc. are used. These materials not only have good wear resistance and corrosion resistance, but also can effectively capture fine dust particles with a diameter of microns. Through reasonable airflow distribution design, ensure that the dust-containing gas passes through each filter bag evenly, and maximize the dust removal efficiency. Generally speaking, the dust removal efficiency of the bag type dust collector for grinding machine can reach more than 99%, or even higher, which effectively reduces the dust concentration in the workshop.

Stability is one of the important indicators to measure the performance of dust removal equipment. The bag filter of the grinder ensures the long-term stable operation of the equipment through precise manufacturing process and strict quality control. Its internal structure is reasonably designed, the air flow channel is smooth, the resistance loss is reduced, and the overall operation efficiency is improved. At the same time, the use of advanced cleaning technologies, such as pulse jetting and vibration cleaning, can regularly remove the dust on the surface of the filter bag, maintain the permeability and filtration efficiency of the filter bag, and extend the service life of the equipment.

With the continuous improvement of the level of industrial automation, the bag filter of the grinder is gradually developing in the direction of intelligence. Modern dust collectors are generally equipped with intelligent control systems, which can monitor the operating status, dust concentration, pressure difference and other key parameters of the equipment in real time, and automatically adjust the cleaning frequency, fan speed and other parameters according to the actual situation to achieve the optimal dust removal effect.

The dust generated during the grinding process is of various types and has a wide distribution of particle sizes, which puts forward high adaptability requirements for dust removal equipment. With its flexible and diverse design features, the bag filter of the grinder can easily cope with various complex working conditions. Whether it is metal dust, non-metallic dust or mixed dust, it can be effectively captured by selecting suitable filter bag materials and adjusting dust removal parameters. At the same time, the dust collector can also be customized according to the actual situation of the production site to meet the personalized needs of different customers.

In the current context of increasing global environmental awareness, the grinder bag dust collector is also actively practicing the concept of green development. By optimizing the equipment structure, improving dust removal efficiency, and reducing energy consumption, the pollution to the environment and the waste of resources are reduced. At the same time, some high-end dust collectors also use advanced technologies such as waste heat recovery and exhaust gas purification to achieve the comprehensive utilization of energy and harmless treatment of waste, creating greater economic and social benefits for enterprises.

The grinder bag dust collector plays an increasingly important role in industrial production with its technical advantages such as efficient filtering capacity, stable and reliable operating performance, intelligent control system, flexible and diverse adaptability, and green concept of energy saving and environmental protection. In the future, with the continuous advancement of industrial technology and the increasingly stringent environmental protection standards, the grinder bag dust collector will continue to maintain its leading position and contribute more to the sustainable development of enterprises and environmental protection.

English

English Español

Español عربى

عربى