How do the specific blade design and cylindrical hub structure help improve the efficiency of the T35 axial flow fan?

Liyang Zhongxing Environmental Protection Machinery Corporation Limited, with its strong professional R&D team and technical service team, not only continues to export new products with excellent cost performance to the market, but also demonstrates remarkable technology in the design and manufacturing of T35 axial flow fans. Advantage. Especially in the innovative application of blade design and cylindrical hub structure, the company has achieved a significant improvement in fan efficiency, which is specifically reflected in the following aspects:

Advanced blade design

Optimized aerodynamic performance: The blade shape of the T35 axial flow fan has undergone precise fluid dynamics simulation and optimization to ensure that the blades can minimize air resistance and eddy current losses during rotation. This design makes the air flow smoother and improves the aerodynamic efficiency of the fan, thereby producing greater air volume or pressure under the same power.

Reduce noise: The unique blade design also takes into account noise control factors. By optimizing the angle of attack and twist of the blades, it effectively reduces the aerodynamic noise when the fan is running, providing users with a quieter working environment.

Enhanced stability: The optimized blade design also enhances the operational stability of the fan, reduces vibration caused by uneven air flow, and extends the service life of the equipment.

Cylindrical hub structure

Reduce energy loss: Compared with traditional designs, the cylindrical hub structure reduces the air flow resistance caused by the hub shape, allowing more energy to be directly converted into effective wind flow energy, thus improving the overall efficiency of the fan.

Improve structural strength: The cylindrical hub is made of high-strength materials, combined with precise processing technology, which not only ensures the stable operation of the fan, but also improves its ability to withstand high-speed rotation and complex working conditions, reducing vibration or stress concentration. risk of failure.

Optimized space utilization: This design also optimizes the spatial layout inside the fan, making the overall structure of the fan more compact, making it easier to install and maintain, while also improving the efficiency of the fan to a certain extent.

Liyang Zhongxing Environmental Protection Machinery Corporation Limited has significantly improved the efficiency of the T35 axial flow fan through its unique blade design and cylindrical hub structure. It not only meets the high performance requirements under standard working conditions, but also has the ability to The ability to operate stably under a wider range of working conditions. These technical advantages are the solid foundation for the company to continue to provide customers with high-quality, efficient and reliable products.

What specific measures has the T35 axial flow fan manufacturer taken to reduce the noise of the T35 axial flow fan?

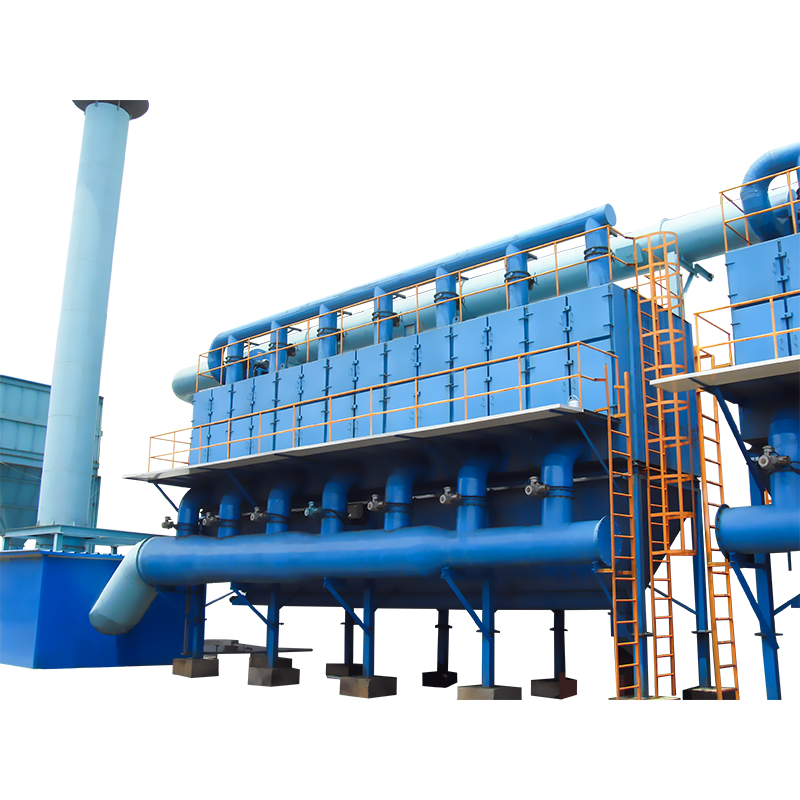

Liyang Zhongxing Environmental Protection Machinery Corporation Limited, as a leader in the field of mining dust collectors, not only focuses on researching, designing and manufacturing various types of efficient and reliable dust removal equipment, but also relies on its advanced equipment, complete computer management system and powerful The technical strength has established an excellent brand image in the industry. One of the company's significant advantages lies in its continuous optimization and innovation of product performance, especially in reducing the noise of the T35 axial flow fan, it has adopted a number of scientific and effective specific measures:

Optimized impeller design: The company has carefully designed the impeller of the T35 axial flow fan. By adjusting the shape, angle and distribution of the blades, the vortex and turbulence generated by the air flow on the blade surface are reduced, thereby reducing the generation of noise from the source. This design not only improves the aerodynamic efficiency of the fan, but also significantly reduces operating noise.

Use of low-noise motors: Zhongxing Environmental Protection Machinery Co., Ltd. uses high-quality low-noise motors as the power source. The vibration and noise generated by the motor itself during operation are extremely low, further reducing the overall noise output of the fan.

Dynamic balance correction: All impellers undergo strict dynamic balance correction before leaving the factory to ensure optimal balance during rotation and avoid vibration and noise caused by imbalance.

Application of sound insulation materials: In the shell and key parts of the fan, the company cleverly uses high-efficiency sound insulation materials, such as porous sound-absorbing panels, damping materials, etc., to effectively absorb and isolate the noise generated by the operation of the fan, providing users with a quieter working environment.

Intelligent control system: Through the advanced computer management system, the company can achieve precise monitoring and intelligent adjustment of the operating status of the fans, adjust the fan speed and air volume according to actual needs, avoid the increase in noise caused by excessive operation, and achieve the dual effect of energy saving and noise reduction.

Aerodynamic optimization: During the design stage, the company conducted in-depth research on the air inlet, outlet and air duct layout of the fan, and achieved the purpose of reducing noise by optimizing the air flow path and reducing air flow impact and friction.

Liyang Zhongxing Environmental Protection Machinery Corporation Limited has achieved effective noise control by optimizing product design, selecting high-quality components, applying sound insulation technology and intelligent control and other means to reduce the noise of T35 axial flow fans, and provide customers with A quieter and more efficient environmentally friendly equipment solution. At the same time, the company's product performance under standard working conditions is also excellent, ensuring the stable operation of the equipment under various environmental conditions.

English

English Español

Español عربى

عربى