In modern industrial production, dust pollution is a problem that cannot be ignored, especially in metal processing, chemical, pharmaceutical and food industries. Among them, grinders, as common production equipment, will generate a lot of dust during operation. These dusts not only affect the cleanliness of the production environment, but may also pose a threat to the health of employees. It is particularly important to choose an efficient and reliable bag dust collector (Bag Type Dust Collector) to match the grinder.

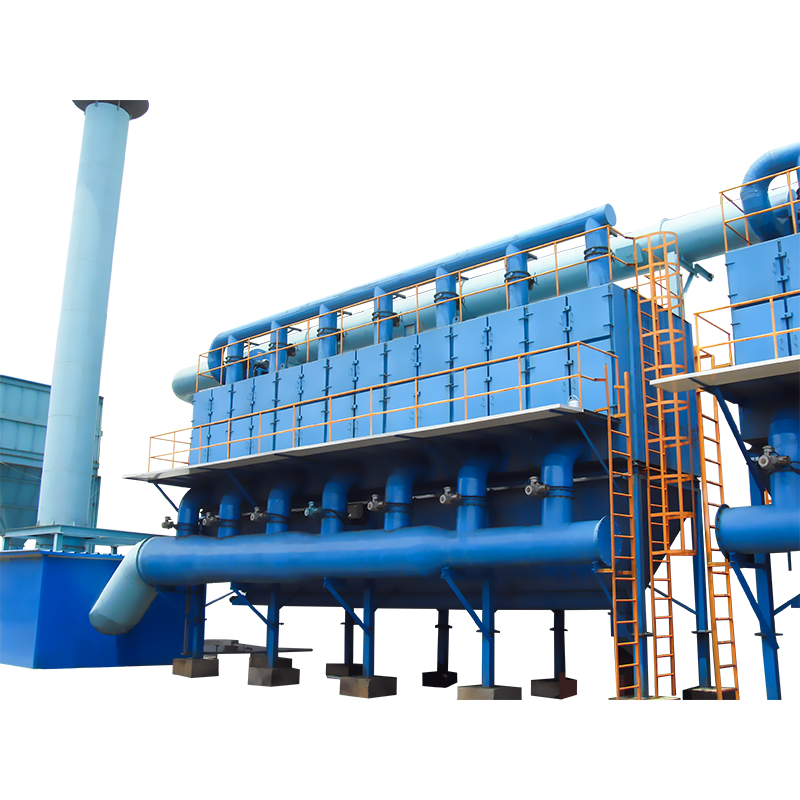

Bag Type Dust Collector for Grinding Machine is an efficient and energy-saving air purification equipment that separates dust particles in the air through bag filter media and returns clean air to the work area or discharges it to the outside. This dust collector has the advantages of high dust collection efficiency, large flue gas processing volume, long service life and low maintenance cost, so it has been widely used at home and abroad.

For grinders, the main function of Bag Type Dust Collector for Grinding Machines is to collect and filter dust generated during the grinding process. When the grinder is working, the material is fed into the grinding chamber and crushed into the required powder through the impact, shearing and friction between the high-speed rotating active chain ring crankshaft and the fixed teeth. In this process, a large amount of dust will be generated. If there is no effective dust removal equipment, this dust will not only diffuse throughout the working area, but also cause wear and tear on the equipment and even cause safety hazards.

The grinder bag dust collector can effectively capture this dust through its unique filtering mechanism. The dust collector bag is usually made of durable fiber material with good filtering performance. When the dust-laden air passes through the bag, the dust particles are trapped on the surface of the bag, and the clean air is discharged through the micropores of the bag. As more and more dust accumulates on the surface of the bag, the dust collector will automatically start the pulse jet device, use compressed air to shake off the dust on the surface of the bag, and collect it in the ash hopper below, thereby maintaining the continuous filtering capacity of the bag.

When choosing a bag dust collector, you need to consider multiple factors to ensure that it can meet the specific needs of the grinder. The first is the dust collector's handling air volume, which depends on the amount of dust generated by the grinder. If the air volume is too small, the dust removal effect will be poor; if the air volume is too large, energy will be wasted. The second is the material of the bag. Different dust characteristics require different filter media. For example, for high temperature, humid or corrosive dust, it is necessary to select bags of special materials to ensure their service life and filtering effect.

In practical applications, bag dust collectors for grinders have achieved remarkable results. In the metal polishing and glass processing industries, bag dust collectors are widely used in the dust treatment of grinders. By installing bag dust collectors, not only dust pollution is effectively controlled, but also the working environment of employees is improved and production efficiency is improved.

With the continuous improvement of environmental awareness and the continuous advancement of technology, bag dust collectors for grinders are also constantly innovating and improving. For example, some new bag dust collectors use more efficient filtering materials and smarter control systems, which can achieve higher dust removal efficiency and lower energy consumption. At the same time, some dust collectors are also equipped with wet dust removal devices, which separate dust from the air by spraying water, further improving the dust removal effect.

English

English Español

Español عربى

عربى