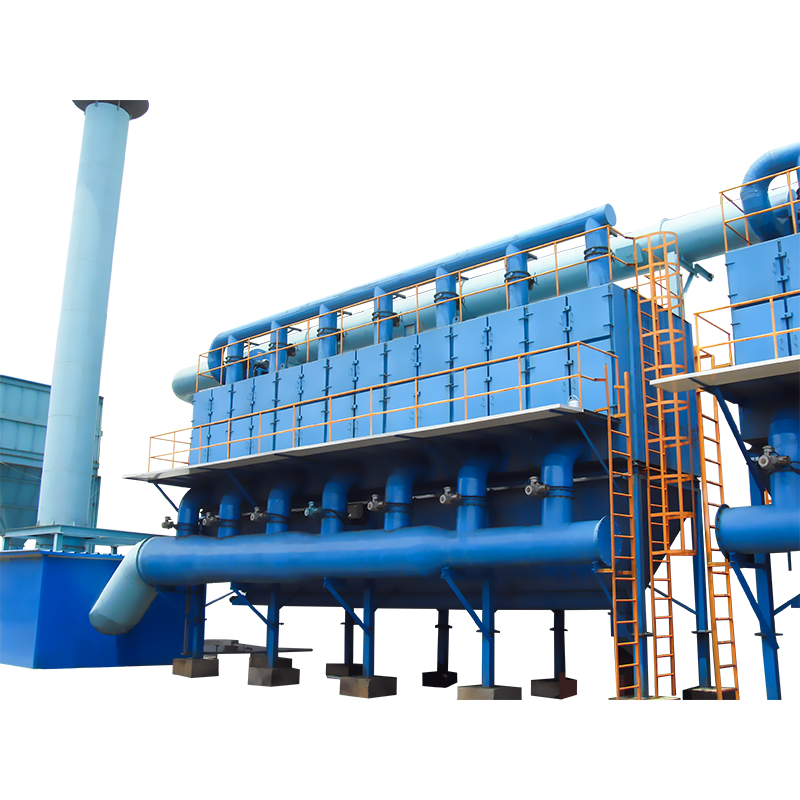

In today's society, environmental issues have become the focus of global attention. As one of the main sources of environmental pollution, industrial emissions are particularly important for governance. Against this background, Environment protection Bag Filter Dust Collector has made great achievements in the field of environmental protection with its efficient and stable dust removal performance, and has become the preferred dust removal equipment for many industrial enterprises.

The core of Environment protection Bag Filter Dust Collector lies in the "bag" - the dust removal bag. These bags are usually made of high-temperature and corrosion-resistant synthetic fibers or glass fibers and have good filtering performance. When working, the dust-laden gas first enters the dust collector box through the air inlet, and then the airflow forms a vortex outside the bag. The larger dust particles are directly settled at the bottom of the ash hopper due to inertia, while the fine dust is captured by the fiber layer on the surface of the bag. As the pressure difference between the inside and outside of the bag gradually increases, when it reaches the set value, the pulse cleaning system automatically starts, and the bag expands rapidly through the instantaneous injection of high-pressure gas, shaking off the dust attached to the surface to achieve the purpose of cleaning. The cleaned dust falls into the ash hopper and is discharged through the ash discharge device, while the purified gas is discharged from the air outlet to achieve standard emissions.

Significant advantages of Environment protection Bag Filter Dust Collector

High efficiency dust removal: The bag filter has a very high capture efficiency for fine dust, which can reach more than 99%, and can effectively remove tiny particles such as PM2.5, meeting strict environmental emission standards.

Strong adaptability: Whether it is a high temperature, high humidity or highly corrosive gas environment, by selecting the right bag material, the bag filter can operate stably and show strong adaptability.

Stable operation: The structure is reasonably designed, maintenance is simple, and the failure rate is low, ensuring long-term continuous and stable operation, reducing downtime and maintenance costs.

Energy saving and environmental protection: Compared with other dust removal methods, bag dust collectors have lower energy consumption, and the recovered dust can be reused, which promotes the recycling of resources and conforms to the concept of green production.

In the tide of environmental protection, bag dust collectors play an indispensable role. It is not only widely used in traditional heavy pollution industries such as electricity, steel, cement, and chemicals, effectively reducing dust emissions in industrial waste gas, but also gradually penetrates into food processing, pharmaceutical manufacturing and other fields with extremely high environmental requirements to ensure the cleanliness and safety of the production environment. Especially in the current context of global climate change and increasingly severe air quality problems, the efficient dust removal capacity of bag dust collectors has made great contributions to reducing haze weather, improving air quality, and protecting human health.

With the continuous advancement of technology, intelligence and automation have become new trends in the development of bag dust collectors. By integrating technologies such as the Internet of Things and big data analysis, remote monitoring and intelligent adjustment of the dust removal process can be achieved, which further improves the dust removal efficiency and operation management level, and provides a more accurate and efficient solution for environmental protection.

English

English Español

Español عربى

عربى