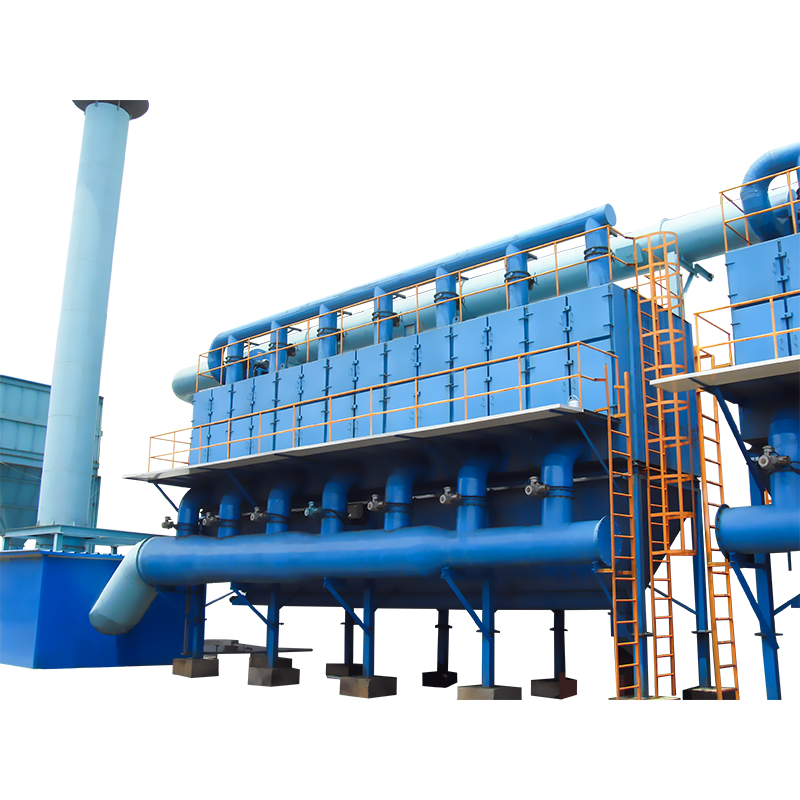

In modern industrial production, environmental protection and resource conservation have become the core elements of sustainable development of enterprises. Faced with increasingly stringent environmental regulations and the need for efficient production, the Industrial Pulse Jet Blowing Bag Dust Collector has become an important choice for many companies to optimize the production environment and improve production efficiency with its performance and wide application fields.

The Industrial Pulse Jet Blowing Bag Dust Collector is an efficient dust removal equipment that effectively captures suspended dust and mist in the gas through the bag filtration principle. Its core working principle is that the dust-containing gas is blocked by the filter bag inside the bag dust collector, the dust particles are trapped on the surface of the bag, and the clean gas is discharged through the bag. As the dust accumulates on the surface of the bag, the dust collector will start the pulse spray system, using compressed air to spray the bag at high pressure in a short time, causing the bag to expand instantly, thereby shaking the dust attached to the surface of the bag into the ash hopper below, realizing the regeneration of the bag and continuous dust removal.

Modern industrial pulse jet bag dust collectors use advanced filter materials, such as PTFE film-coated polyester bags, which not only have heat and corrosion resistance, but also can effectively capture fine dust, ensuring dust removal efficiency of more than 99%.

Through the integrated PLC control system, the industrial pulse jet bag dust collector can automatically adjust the pulse jet frequency according to parameters such as gas flow and bag pressure difference to maximize the dust removal effect while reducing energy consumption and operating costs.

In order to meet the needs of production lines of different sizes and types, the industrial pulse jet bag dust collector adopts a modular design for easy installation, commissioning and maintenance. Users can flexibly configure the scale and number of dust collectors according to actual production conditions to achieve optimal resource allocation.

During operation, the industrial pulse jet bag dust collector can effectively reduce dust emissions and reduce air pollution, in line with international environmental standards. At the same time, by recycling dust, enterprises can also reuse resources and reduce production costs.

Industrial pulse jet bag dust collectors have shown strong application potential in many industries. In the energy and mining industry, it can effectively capture dust generated during the processing of materials such as coal and ore, improve the working environment, and protect the health of employees. In the building materials industry, it is used to treat dust generated during the production of cement, lime, etc., improve product quality, and reduce environmental pollution.

The industrial pulse jet bag dust collector has become an indispensable environmental protection equipment in modern industrial production with its high efficiency, intelligence, and environmental protection. With the continuous advancement of technology and the continuous expansion of applications, it will show its unique value and charm in more fields. In the future, we look forward to seeing more innovative designs and technological breakthroughs to jointly promote the green development of the industrial dust removal field and contribute to building a better home on Earth.

English

English Español

Español عربى

عربى