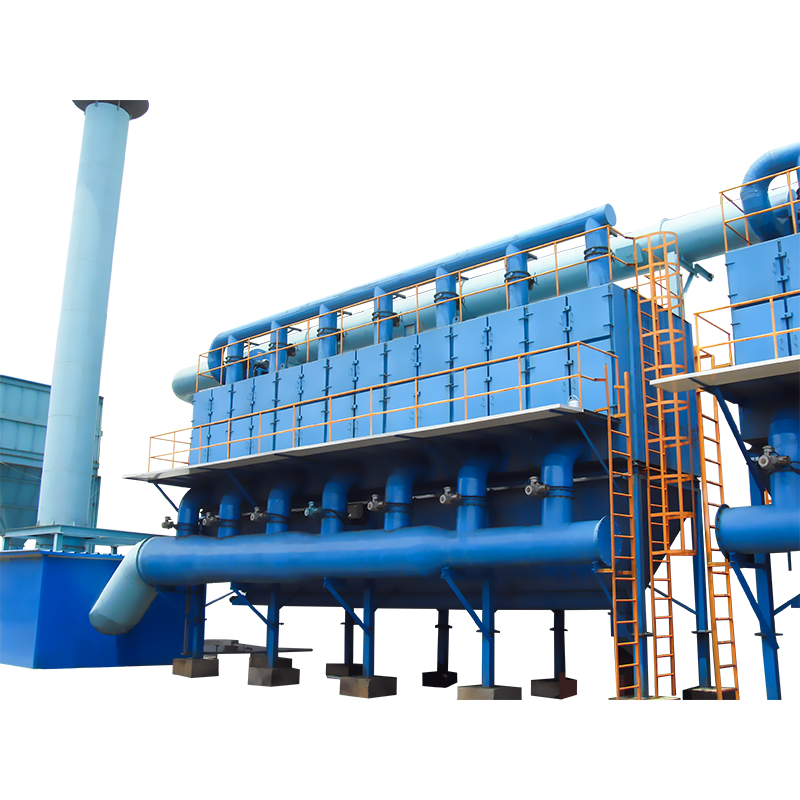

In the industrial world of mechanical roar, the centrifugal fan is like a beating heart, driving the circulation of airflow and giving industrial equipment a steady stream of power. In an era of rapid technological development, the importance of centrifugal fans has become increasingly prominent. It is not only the cornerstone of modern industrial production, but also an indispensable key link in future intelligent manufacturing.

As a gas compression and delivery device, the working principle of the centrifugal fan can be traced back to the windmill in ancient Greece. However, the real centrifugal fan was born during the Industrial Revolution. It throws the gas from the center to the outer edge through a rotating impeller, thereby achieving gas pressurization and delivery. This principle seems simple, but it actually contains complex fluid mechanics and mechanical design wisdom. The ancients said: "If you want to do your job well, you must first sharpen your tools." The efficient operation of centrifugal fans not only depends on precise mechanical manufacturing, but also requires a deep theoretical foundation and continuous technological innovation.

The role of centrifugal fans is everywhere. Whether it is mine ventilation, boiler induced draft, air conditioning ventilation, or sewage treatment, centrifugal fans play a vital role. Its high efficiency, stability and low noise make it an indispensable equipment in all walks of life. The application of centrifugal fans not only improves production efficiency and optimizes the working environment, but also promotes the process of industrial modernization.

The development history of centrifugal fans is also a history of scientific and technological progress. Due to the limitations of materials and processing technology, early centrifugal fans had low efficiency and high noise. With the continuous progress of material science, processing technology and fluid mechanics theory, modern centrifugal fans have been greatly improved in efficiency, noise control and reliability.

The design of centrifugal fans is a combination of science and art. As the core component of centrifugal fans, the shape, size, angle and other factors of the impeller directly affect the performance of the fan. The impeller design of modern centrifugal fans must not only consider aerodynamics, but also take into account material strength and manufacturing process. Through computational fluid dynamics (CFD) simulation and continuous optimization of experimental data, designers can create more efficient and stable centrifugal fans.

The development of centrifugal fans is inseparable from innovation. Science and technology are changing with each passing day, and the continuous emergence of new materials and new technologies has provided new possibilities for the design and manufacture of centrifugal fans. Modern centrifugal fans have not only made a qualitative leap in performance, but also made important steps in intelligence and digitalization. Through the Internet of Things and big data technology, the operating status of centrifugal fans can be monitored and adjusted in real time, and fault diagnosis and maintenance are more efficient and accurate. This intelligent transformation not only improves the operating efficiency of the equipment, but also extends its service life and reduces maintenance costs.

Centrifugal fans, like the heart of industry, drive the pulse of modern production. Every rotation of it is an interpretation of industrial progress; every roar of it is a tribute to scientific and technological innovation. In this era of continuous progress, centrifugal fans will continue to use their powerful power to push the wheels of industry forward. May we meet every challenge and embrace every opportunity with unremitting efforts and firm beliefs, so that the melody of centrifugal fans can play a more brilliant movement on the stage of industrial development.

Time flies, and years pass by. No matter how the future changes, centrifugal fans will always be an indispensable and important equipment in the industrial world.

English

English Español

Español عربى

عربى