In modern industrial production, screw conveyors have become an indispensable and important equipment in all walks of life. With the rapid development of science and technology, the intelligent and digital transformation of screw conveyors has become a general trend, further improving its efficiency and reliability in material transportation.

Intelligent and digital transformation is an inevitable trend in the development of modern industry. As a traditional mechanical equipment, screw conveyors can not only achieve more efficient material transportation, but also greatly reduce failure rate and maintenance costs through the application of intelligent and digital technologies. Intelligent screw conveyors can monitor the operating status in real time, automatically adjust working parameters, and optimize conveying efficiency, thereby improving the flexibility and response speed of the entire production system.

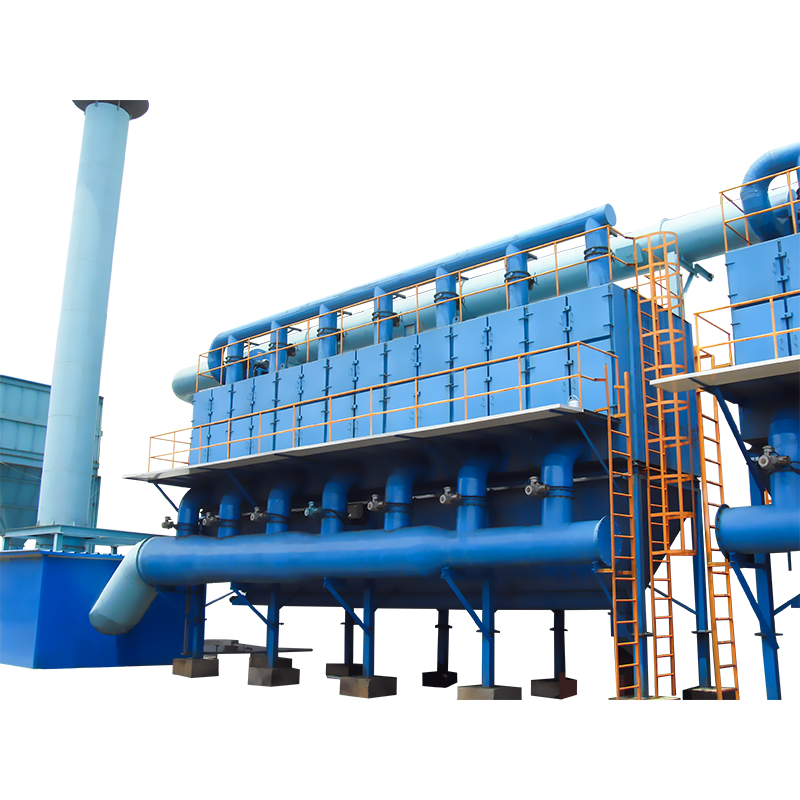

Internet of Things (IoT) technology is the basis for realizing the intelligence of screw conveyors. By installing various sensors on the key components of the screw conveyor, such as temperature sensors, pressure sensors, vibration sensors, etc., the data of the equipment's operating status can be collected in real time. These data are transmitted to the central control system through the network to realize remote monitoring and management of the equipment.

Big data analysis technology plays an important role in the intelligence of screw conveyors. By analyzing the data collected by the sensors, the abnormal status of the equipment can be discovered in time, possible fault points can be predicted, maintenance can be carried out in advance, and sudden shutdown of the equipment can be avoided. In addition, big data analysis can also help optimize the operating parameters of screw conveyors and improve the efficiency and stability of material transportation.

In the grain processing industry, screw conveyors are used to transport materials such as grains and flour. Through the application of digital technology, grain processing companies can achieve precise control of the production process and ensure the stability of product quality. In addition, the intelligent system can flexibly adjust the working state of the conveyor according to production needs to improve the flexibility and efficiency of production.

In sewage treatment plants, screw conveyors are used to transport sludge and solid waste. Through intelligent transformation, sewage treatment plants can achieve full monitoring of the conveying process to ensure efficient treatment and transportation of sludge and waste. The intelligent system can also dynamically adjust the operating state of the conveyor according to the load of sewage treatment, thereby improving the efficiency and reliability of the entire sewage treatment system.

The intelligent and digital transformation of screw conveyors not only improves the performance and reliability of equipment, but also has a far-reaching impact on the future development of industry. The application of intelligent and digital technologies can significantly improve production efficiency, reduce operating costs, and enhance the market competitiveness of enterprises. Through real-time monitoring and predictive maintenance, the service life of equipment can be extended and the losses caused by unexpected downtime can be reduced. Intelligent and digital transformation provide important support for the realization of intelligent manufacturing and Industry 4.0, and promote the upgrading and transformation of the entire industrial system.

Screw conveyors, like the silent pushers of industry, have been rejuvenated in the wave of intelligent and digital transformation. Every rotation of it is an interpretation of industrial progress; every data transmission of it is a tribute to scientific and technological innovation. In this era of continuous progress, screw conveyors will continue to push the wheels of industry forward with their powerful power and intelligent technology. May we meet every challenge and embrace every opportunity with unremitting efforts and firm beliefs, so that the melody of screw conveyors can play a more brilliant movement on the stage of industrial development.

English

English Español

Español عربى

عربى