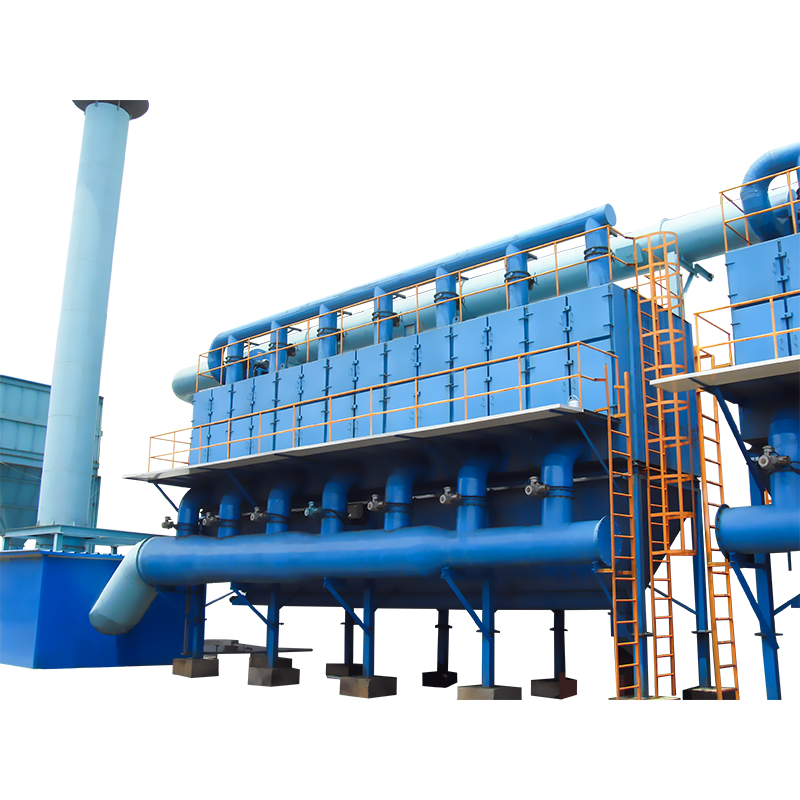

The pulse jet system is the core cleaning mechanism of the ZXMC Series Pulse Dust Collector. The system uses a powerful airflow generated by the instantaneous release of compressed air to pulse-jet the filter bags, thereby removing dust particles attached to the filter bags. This cleaning method is both efficient and energy-saving, which can greatly extend the service life of the filter bags and reduce maintenance costs.

Working principle of the pulse jet system

Compressed air reserve: The pulse jet system first compresses the air through the compressor and stores it in the air tank. This compressed air is the power source for the jetting process.

Pulse valve control: When the dust on the filter bag accumulates to a certain extent, the control system will issue a command to open the pulse valve quickly. The pulse valve is a key component connecting the air tank and the jet pipe. Its opening time is extremely short, but it is enough to generate a strong airflow.

Jetting process: When the pulse valve is opened, the compressed air in the air tank is instantly released and sprayed to the filter bag through the jet pipe. This powerful airflow blows off the dust particles on the filter bag and makes it fall back into the dust hopper.

Filter bag regeneration: After pulse spraying, the dust on the surface of the filter bag is cleaned and its filtering performance is restored. At this time, the filter bag is in normal working condition again and continues to capture dust particles in the air.

Advantages of pulse spraying system

Efficient cleaning: The pulse spraying system adopted by ZXMC Series Pulse Dust Collector can release a strong airflow in a very short time. This instantaneous high-pressure airflow can effectively remove the dust on the filter bag. Compared with traditional mechanical vibration or manual cleaning methods, the pulse spraying system has higher cleaning efficiency and lower energy consumption. The working principle of the pulse spraying system is to release compressed air in a very short time to generate a strong pulse airflow. This airflow acts directly on the filter bag through the spraying pipe, so that the dust attached to the surface of the filter bag falls off quickly. At the same time, due to the instantaneous and concentrated nature of the pulse airflow, it can ensure a more uniform and thorough cleaning effect.

Extended service life: Since the filter bag is cleaned in a timely and effective manner, its service life is greatly extended. This helps to reduce maintenance costs and improve the overall economic benefits of the equipment.

Energy saving and environmental protection: The pulse spraying system uses compressed air as a power source, without additional energy consumption. At the same time, since the cleaning process is short and efficient, the energy consumption and emissions during equipment operation are reduced.

Intelligent control: The ZXMC Series Pulse Dust Collector uses an advanced PLC (Programmable Logic Controller) system to achieve real-time monitoring and automatic adjustment of the dust collector's operating status. The PLC system can automatically complete the pulse jet cleaning of the filter bag, the control of the emission system, and the fault alarm of the equipment according to the preset control logic. The intelligent control system detects gas concentration, temperature, pressure and other parameters in real time through sensors installed at the air inlet, air outlet, ash outlet and other locations, and transmits these parameters to the PLC control system. The PLC system accurately controls each component of the equipment based on these parameters and the preset control logic to ensure that the dust collector is always in the best working condition. The intelligent control system can automatically adjust the frequency and time of pulse jetting according to the actual situation of the production site to avoid energy waste caused by excessive cleaning. At the same time, the system can also automatically adjust the flow rate of the emission system and the height of the emission port according to the concentration of the exhaust gas to meet environmental protection requirements.

The pulse jet system adopted by the ZXMC Series Pulse Dust Collector is an efficient, energy-saving and environmentally friendly cleaning mechanism. The system uses the powerful airflow generated by the instantaneous release of compressed air to perform pulse-type spray cleaning on the filter bags, ensuring that the filter bags always maintain good filtering performance. This cleaning method not only extends the service life of the filter bags, reduces maintenance costs, but also improves the overall economic benefits of the equipment. At the same time, the pulse spray system also has an intelligent control function, which can automatically adjust the cleaning frequency and time according to actual conditions, achieving more energy-saving and efficient operation.

English

English Español

Español عربى

عربى