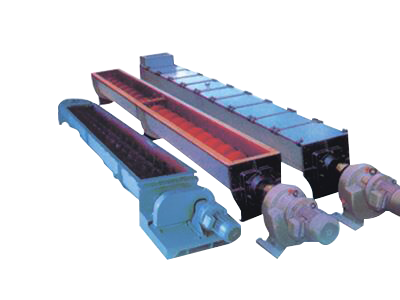

How does the material of the spiral blades of the LS type screw conveyor affect the conveying efficiency and wear resistance?

At Liyang Zhongxing Environmental Protection Machinery Corporation Limited, we always adhere to the corporate purpose of "high standards, refinement, and zero defects". We not only regard quality as the lifeline of the company, but also are committed to leading the future development of the environmental protection machinery industry through technological innovation and excellent quality. As a leader in the industry, our LS type screw conveyor fully reflects this concept in design and production, especially in the selection of the material of the spiral blades, which is carefully considered to ensure that the product is both efficient and durable.

The material of the spiral blades of the LS type screw conveyor has a direct impact on the conveying efficiency and wear resistance. Specifically, we use a variety of high-quality alloy steel or stainless steel materials to manufacture spiral blades according to different material characteristics and use environments:

Improved wear resistance: For materials that need to be handled with strong abrasiveness, such as ore, gravel, etc., we use high wear-resistant alloy steel as the material of the spiral blades. This material has undergone special heat treatment and has a high surface hardness. It can effectively resist the friction and wear of the material during the conveying process, thereby extending the service life of the equipment and reducing maintenance costs.

Optimized conveying efficiency: Considering the requirements of material fluidity and conveying efficiency, the spiral blades we designed not only focus on wear resistance, but also on surface finish and shape accuracy. The smooth surface can reduce the resistance of the material during the conveying process and improve the fluidity of the material, thereby speeding up the conveying speed and improving the overall conveying efficiency.

Strong adaptability: We provide customized spiral blade material selection for different temperature and humidity conditions of conveying materials. For example, for materials with a conveying temperature of ≤80℃, standard wear-resistant stainless steel or alloy steel can meet the needs; for conveying temperatures of >80℃ or wet materials, we recommend the use of special materials that are resistant to high temperatures and corrosion to ensure that the spiral blades can still maintain stability and efficiency in harsh environments.

The LS type screw conveyor of Liyang Zhongxing Environmental Protection Machinery Corporation Limited, with its excellent spiral blade material selection and design, not only ensures high efficiency and stability during the conveying process, but also greatly improves the wear resistance and service life of the equipment, bringing customers a more reliable and economical solution. This is also one of the important advantages for our company to maintain its leading position in the environmental protection machinery industry and continue to lead the development of the industry.

How does the screw diameter of the LS screw conveyor affect the conveying capacity of the conveyor?

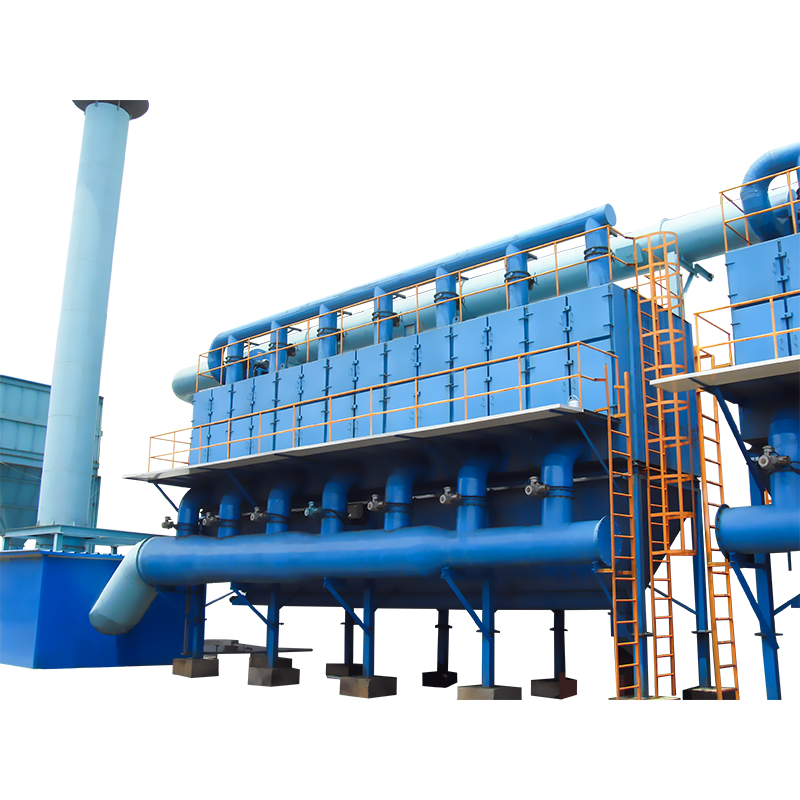

Liyang Zhongxing Environmental Protection Machinery Corporation Limited, as a leader in the industry, has always adhered to the core values of "treating employees, customers and society with integrity". It has not only won wide recognition in the market, but also successfully established a solid cooperative relationship with heavyweight enterprises such as the Northern Thermal Power Design Institute and Guodian Equipment Company, and achieved rapid development of the company through a horizontal integration strategy. The company's product line covers multiple fields such as electricity, metallurgy, chemical industry, building materials (cement), construction engineering, casting, mining, etc., demonstrating its strong comprehensive strength and wide market adaptability.

Among the many products of Zhongxing Environmental Protection Machinery Corporation Limited, the LS screw conveyor has become a highlight in the market with its excellent performance and flexible configuration. Regarding how the screw diameter of the LS screw conveyor affects the conveying capacity of the conveyor, the following points are the key advantages:

Conveying volume adjustment: The screw diameter is an important factor that directly affects the conveying capacity of the screw conveyor. As the screw diameter increases, the amount of material that the conveyor can accommodate and push at the same speed also increases, thereby improving the overall conveying efficiency. Therefore, when choosing a screw conveyor, choosing a reasonable screw diameter according to the specific material conveying requirements can maximize the production requirements.

Strong adaptability: The LS screw conveyor provided by Zhongxing Environmental Protection has a wide range of screw diameters, with 11 specifications from 100mm to 1250mm. This diverse selection makes the equipment suitable for production lines of different scales and outputs. Whether it is a small laboratory or a large industrial production site, you can find the most suitable screw diameter to ensure the efficiency and stability of the conveying process.

Customized service: In addition to standard screw conveyors, the company also provides customized services. For special working conditions or special material conveying needs, customers can make special requirements when selecting the model. The company will adjust the screw diameter, length and other parameters according to the actual situation to ensure that the equipment perfectly matches the actual needs of customers. This flexible customization capability further enhances Zhongxing Environmental Protection's competitiveness in the market.

High efficiency and energy saving: Reasonable screw diameter design not only improves the conveying capacity, but also helps to achieve high efficiency and energy saving. While ensuring the conveying efficiency, by optimizing the matching relationship between the screw diameter and the motor power, energy consumption can be significantly reduced and operating costs can be reduced. This is undoubtedly an important consideration for companies pursuing green production, energy conservation and emission reduction.

The LS screw conveyor of Liyang Zhongxing Environmental Protection Machinery Corporation Limited has established a good reputation in the industry for its flexible screw diameter design, strong conveying capacity, wide adaptability and efficient customized services. Whether in terms of product performance or service quality, it fully reflects the company's "integrity-based" business philosophy and a deep understanding of customer needs.

English

English Español

Español عربى

عربى