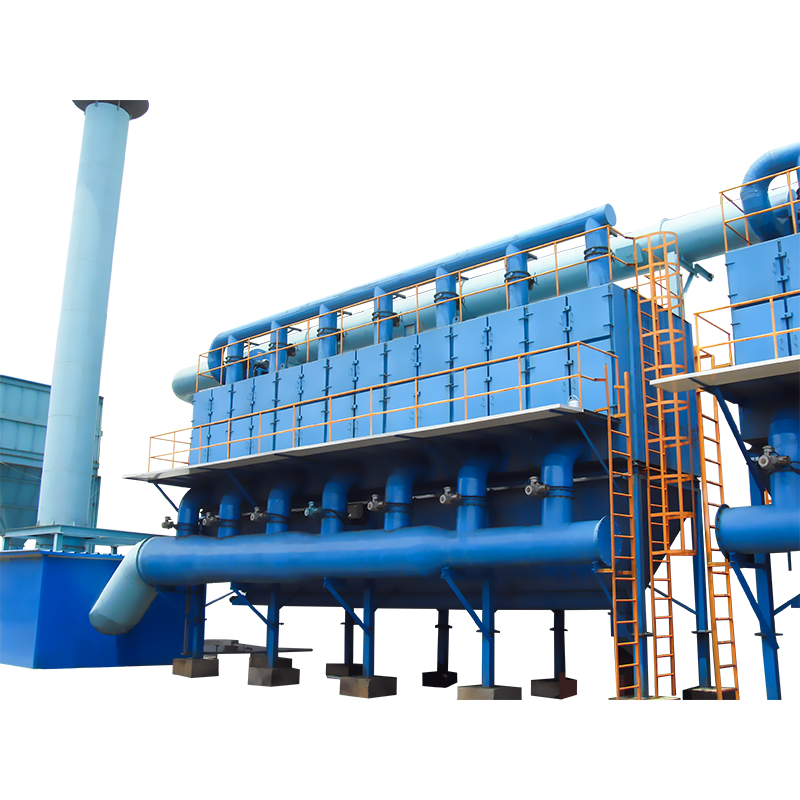

Air velocity is a crucial parameter in the design and operation of dust collectors. The air flow speed within a reasonable range not only helps to speed up the settling rate of particulate matter, but also significantly improves the dust removal efficiency. However, too high air flow speed may also cause a series of problems, such as increasing air flow resistance, thus affecting the overall operating efficiency of the dust collector. Therefore, when optimizing dust collector performance, we need to carefully weigh our airflow speed choices.

First, let’s take a closer look at the impact of airflow speed on dust collection efficiency. During the dust removal process, the particles are pushed by the air flow and their own gravity, and settle toward the dust collecting plate or filter bag. When the air flow speed is moderate, particles can be captured quickly and effectively, thereby improving dust removal efficiency. This is because an appropriate airflow speed can ensure that the particles receive sufficient driving force during the settling process, while avoiding excessive eddies and turbulence that may lead to secondary dusting of the particles.

However, problems arise when the air velocity is too high. Excessively high air flow speed will increase the air flow resistance and make the air flow distribution inside the dust collector uneven. This will not only increase the energy consumption of the dust collector, but may also cause the air flow velocity in some areas to be too low, thus affecting the settling effect of particulate matter. In addition, too high air flow speed may also increase the wear and blockage of the filter bag, shorten the service life of the filter bag, and further affect the operating efficiency of the dust collector.

In order to balance the impact of air flow speed on dust removal efficiency and operating efficiency, we need to take a series of measures. First of all, during the design stage of the dust collector, the range of air flow velocity should be reasonably determined based on factors such as the characteristics of the particulate matter and the processing capacity. Secondly, during the operation of the dust collector, changes in air flow speed should be regularly monitored and adjusted according to the actual situation. For example, when the processing capacity increases, the air flow speed can be appropriately increased to maintain the dust removal efficiency; when the filter bag is clogged, the air flow speed should be reduced to reduce the wear of the filter bag.

In addition, we can also optimize the airflow distribution by improving the structure and layout of the dust collector. For example, adopt reasonable air inlet and outlet design and reduce structures such as elbows and right angles to reduce airflow resistance. At the same time, the arrangement and support structure of the filter bags are optimized so that they can better withstand the force of air flow and extend their service life.

Reasonably increasing the air flow speed is one of the effective means to improve dust removal efficiency. However, in actual applications, we need to make trade-offs and adjustments based on specific circumstances to ensure that the dust collector operates efficiently while also having good economy and reliability.

English

English Español

Español عربى

عربى